Overview

Adept has a new look!

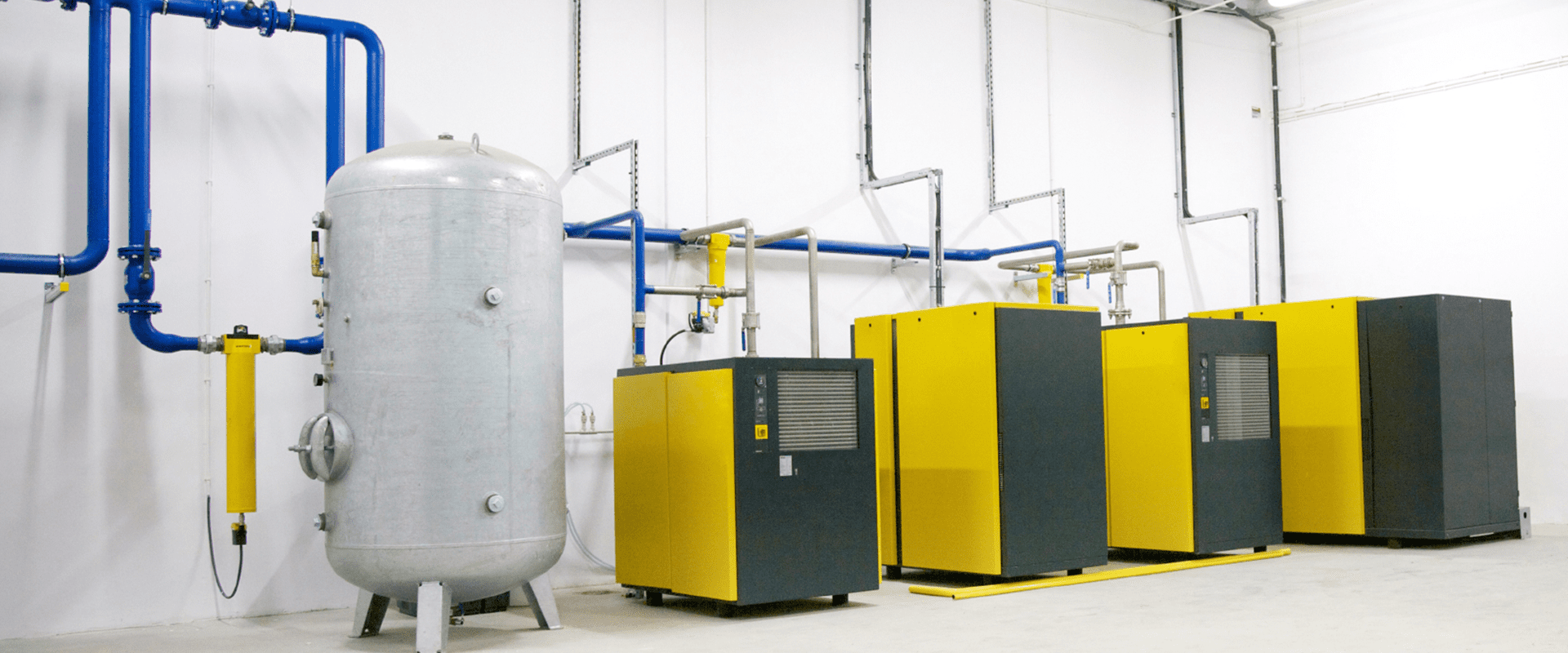

Adept maintains NATA accreditation ISO 17020 Type A for in-service inspection. This is the highest standard of pressure vessel inspection accreditation you can achieve in Australia and means that we are an independent and impartial inspection body.