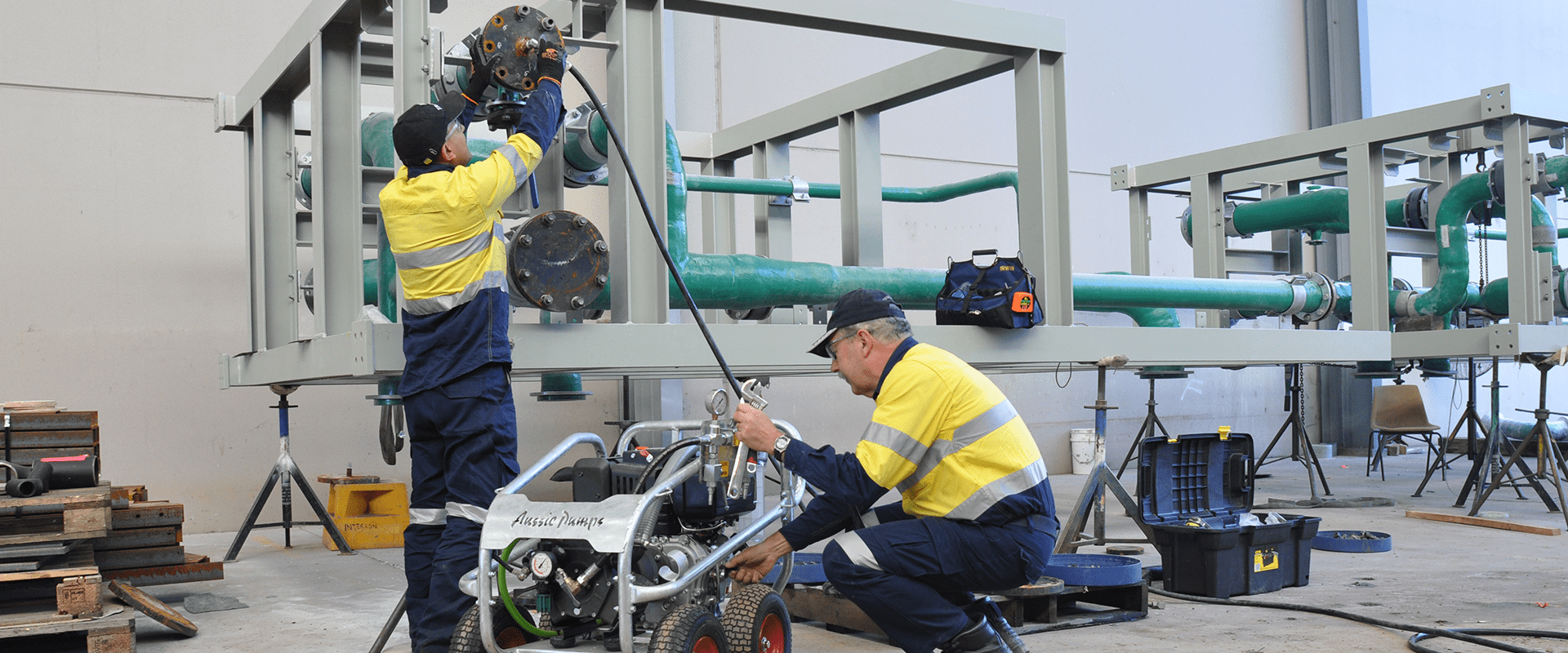

It is critically important to make sure your piping won’t crack or leak its contents. Piping needs to be inspected in the AS/NZS 3788 standard. Adept performs visual pipework inspections and can witness your hydrostatic testing to AS/NZS 3788.

Pipes usually contain compressed air, steam, gases or refrigerants like ammonia and are used in a range of industries such as food manufacturing, chemical plants, wineries, hospitals and more. No matter your business, Adept can provide a range of hydrostatic testing to get the job done. We offer quick turnaround, flexibility and, most importantly, work with you to coordinate your hydrostatic testing needs.